Over the many years of blacksmithing I've discerned the best types of equipment needed to perform typical, and some not so typical, blacksmithing techniques. The equipment listed below is available for use by students and each have been arranged to optimize safety and accomodate instruction. Of course, safety is a key concern and students will be instructed on the proper use of the equipment, and must adhere to advice given.

There are also a large variety of hammers, tongs, metal and other miscellaneous items used during instruction..

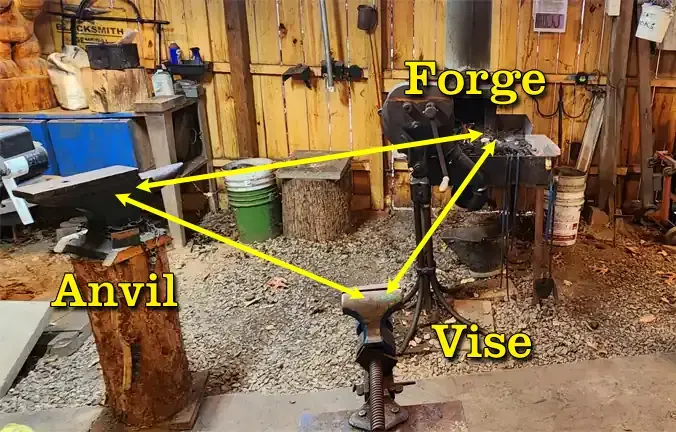

Typical Work Station Layout

Work Station Workflow

Propane Forge

"Lil' John" Hammer

Named in honor of my dad, John Sabo.